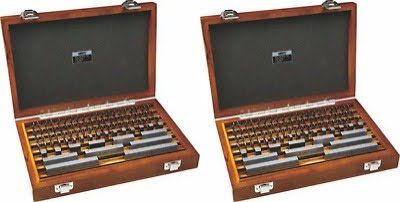

Gauge Block

Have you ever heard of gauge blocks before? In construction-related fields, people often study different types of standard gauge blocks in detail to ensure accurate measurements. The article below will point out a few notes before you decide to purchase a set of gauge blocks—follow along!

1. What are gauge blocks used for?

1.1 Gauge blocks

Gauge blocks are sets of precisely dimensioned blocks used as reference standards in the measurement and calibration of length-measuring instruments such as micrometers, calipers, length measuring machines, and precision machining equipment. Each gauge block has a rectangular shape with two parallel faces that are extremely accurately machined for flatness and length.

As such, gauge blocks help ensure accuracy in comparative measurements, inspection, and equipment calibration, thereby improving product quality and reliability in industrial production. They are indispensable tools in metrology laboratories and precision mechanical manufacturing facilities.

1.2 Key features of gauge blocks

High accuracy: Gauge blocks are manufactured according to international standards such as ISO 3650, JIS, ASME with very small tolerances, ranging from laboratory grades (Grade 0 or AAA) to production use grades (Grade 2 or 3).

Durable materials: Commonly made from chrome carbon alloy steel, carbide, or ceramic (zirconia), they offer excellent wear resistance, rust prevention, and heat tolerance.

Convenient design: The gauge blocks can be wrung together (a method of adhering flat surfaces) to create various measurement sizes, offering flexibility in measuring applications.

Diverse applications: Used to calibrate measuring instruments, check the precision of machining equipment, and measure gaps, thickness, or height in precision mechanical manufacturing.

2. Common types of gauge blocks and their detailed features

2.1 Alloy steel gauge blocks

Material: Chrome carbon alloy steel with high chromium content for rust resistance and increased durability.

Features: Good wear resistance, high mechanical strength, easy to store.

Applications: Commonly used in mechanical factories, metrology labs, for calibrating micrometers, calipers, and other length-measuring tools.

Standards: Manufactured according to international standards such as JIS, DIN, or ASME with various accuracy grades.

2.2 Carbide gauge blocks

Material: Carbide is a hard, durable compound with excellent wear resistance, often used in high-durability applications.

Advantages: Harder than steel, long lifespan, less deformation with extended use.

Applications: Used in harsh manufacturing environments, inspecting products that require high accuracy and durability.

2.3 Ceramic gauge blocks (zirconia)

Material: Zirconia ceramic with exceptional wear resistance, non-rusting, corrosion-free, and non-magnetic.

Advantages: Long-lasting durability, minimally affected by the environment, resistant to heat or chemical deformation.

Applications: Suitable for measurement environments requiring high cleanliness, magnetic resistance, and corrosion resistance.

Standards: Manufactured to JIS Grade 0 or higher with very tight tolerances.

2.4 Types of gauge blocks by shape and function

Rectangular gauge blocks: The most common type, used for wringing together to form different measurement sizes.

Square gauge blocks: No central hole, typically used with external gauge block holders.

Angle gauge blocks: Used for measuring and checking angles or calibrating angle gauges.

Wear blocks: Designed for direct contact with the part or measuring instrument, more resistant to wear.

3. Applications and benefits of using gauge blocks in measurement and calibration

3.1 Calibrating length measuring instruments

Standard gauge blocks are reference standards used to calibrate length-measuring devices such as micrometers, calipers, and automatic length-measuring machines. Calibration ensures that these instruments consistently produce accurate results, thereby improving product quality in manufacturing.

3.2 Inspecting and calibrating machining equipment

In precision mechanical processing plants, gauge blocks are used to inspect the accuracy of machines, ensuring the components produced meet required dimensions. The blocks can be combined to measure different distances or gaps.

3.3 Benefits of using gauge blocks

Improved accuracy: Helps detect errors and allows timely adjustments to instruments and machinery.

Cost savings: Minimizes waste caused by measurement errors, improving production efficiency.

Easy to store and use: Compact, easy to carry, and stored in specialized cases.

High durability: Steel or ceramic materials provide long service life and minimal wear.

Conclusion

Gauge blocks are essential tools in measurement and calibration, ensuring accuracy and product quality across various industries. Steel, carbide, and ceramic gauge blocks with different accuracy levels meet diverse usage needs. Maintenance and sterilization of electronic dummy loads also play an important role in maintaining measurement efficiency.

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-